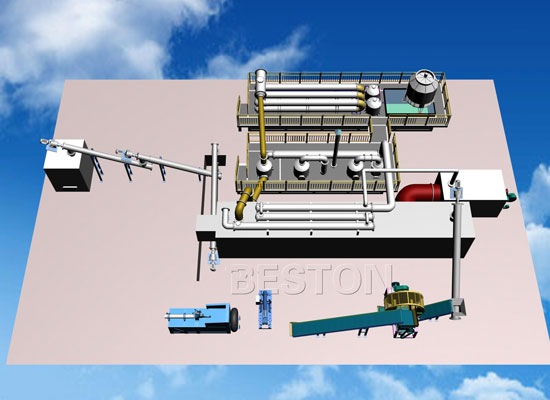

As a professional tyre pyrolysis plant manufacturer, we have manufactured our plants into three operating systems, batching system, semi-continuous system and fully continuous system. The fully continuous waste tyre pyrolysis plant is our featured product which has these advantages.

Firstly, the end-products have high economic values. The continuous tyre pyrolysis plant adopts one kind of advanced technology called pyrolysis. The technology makes full use of high temperature heating, which helps finishing the process of converting tyres into oil. The oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The oil can not only sell in a good price, but also help in relieving energy crisis.

Secondly, the by-products are also useful resources. In the pyrolysis process, there are also something else produced, such as carbon black and steel wire. The carbon black can be used for making construction bricks with clay or used as fuel. The steel wire can be re-sale or reprocessing. Both of the them are in high demand in the market. There is also a little combustible gas produced in the process, the gas can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

Thirdly, compared with traditional batching systems and semi-continuous, the fully continuous tyre pyrolysis system has these advantages.

1. Our auto continuously operating pyrolysis plants have relatively larger processing capacities of 30-50mt per day.

2. The fully continuous plant can achieve feeding of materials and discharging of slags automatically, and can also finish the two steps at the same time, which not only saves time, but also saves fuels.

3. The reactor of our auto operating tire pyrolysis plant is stable and not rotary, which makes the temperature rise and pyrolysis react quickly. This special design makes the whole pyrolysis process efficient and can also save much heating materials.

4. The fully continuous pyrolysis plant can run for 24 hours a day without a stop and needn’t to be cooled before the second batch.

Besides convenient operation and producing products with high economic values, our fully continuous tire pyrolysis plant(30T/D) also has the features of increasing average oil output by 5%, saving energy by 30%-40%, protecting the environment and ensuring safety 100%.

| Model | BLL-20 |

| Daily Capacity | 20-24T |

| Working Method | Fully Continuous |

| Raw Materials | Waste Tyre, Rubber, Plastic, Oil Sludge |

| Reactor Size | D1.4*L11m |

| Pattern | Horizontal & Rotary |

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. |

| Total Power | 71.4kw/h |

| Floor Area (L*W*H) | 45*25*10m |

| Operating Pressure | Constant Pressure |

| Cooling Method | Water Cooling |

| Life Span | 5-8 Years |

Our After-sales Service

1. Design the installation drawings according to your site

2. 1 year warranty, engineers available to service at any time.

3. Periodical call visit, to make sure there is no problems of the equipment.

4. Design specific maintenance program according to different situation of your plant.

5. For each set of continuous tyre pyrolysis system, one technician will be sent to guide your installation, test the machine and train your workers. Besides, we will provide one month’s service for free.

3 thoughts on “Continuous Tyre Pyrolysis Plant”

Comments are closed.